In the continuous development of the beverage market, we can provide different labeling machine according to different material labels, different bottle sizes, different packaging forms, and different speeds.

Bottle labeling machine significantly improves production efficiency in the beverage industry. By automating the labeling process, they reduce the need for manual labor and minimize errors, ensuring that each bottle is labeled accurately and consistently. This not only speeds up the production process, but also reduces waste and rework, thereby saving costs.

-

Rotary hot melt glue labeling machine

This rotary hot melt glue labeling machine is widely used for different sizes of round bottles. It adopts a rotary structure and is suitable for high-speed filling production lines 8000-24000BPH. It uses the roll label materials such as OPP, BOPP and composite paper to replace the PVC shrink label to reduce label material and power costs.

More -

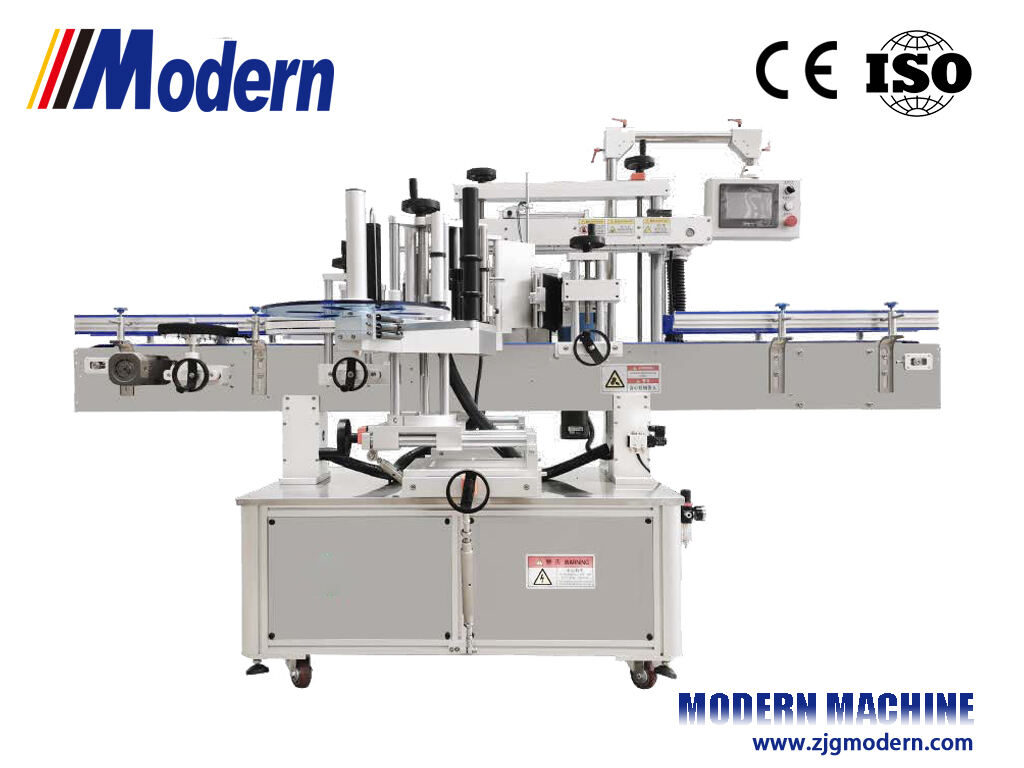

Linear adhesive sticker label applicator

If you are a beginner that have small scale bottling line, this linear adhesive sticker label applicator is an idea machine with lower cost. It’s used for applying self-adhesive labels onto various plastic or glass bottles with different shapes. The whole process is automatic with PLC control.

More -

High speed rotary self-adhesive labeling machine

This rotary self-adhesive labeling machine is a kind of high-speed machine for self-adhesive laminated film or PVC labeling onto bottles. It’s fully automatic labeling process, replacing the manual labeling and enhancing the productivity. It adopts equivalent PLC, positioning module, servo motor and frequency converter.

More -

Automatic sleeve shrink labeling machine

This automatic sleeve shrink labeling machine is suitable for various bottles, such as round bottles, square bottles, oval bottles, etc. It can automatically feed and cut the label film, and accurately sleeve the label, greatly saving labor and improving work efficiency.

More