- Overview

- Parameter

- Video

- Recommended Products

This rotary hot melt glue labeling machine is widely used for different sizes of round bottles. It adopts a rotary structure and is suitable for high-speed filling production lines 8000-24000BPH. It uses the roll label materials such as OPP, BOPP and composite paper to replace the PVC shrink label to reduce label material and power costs.

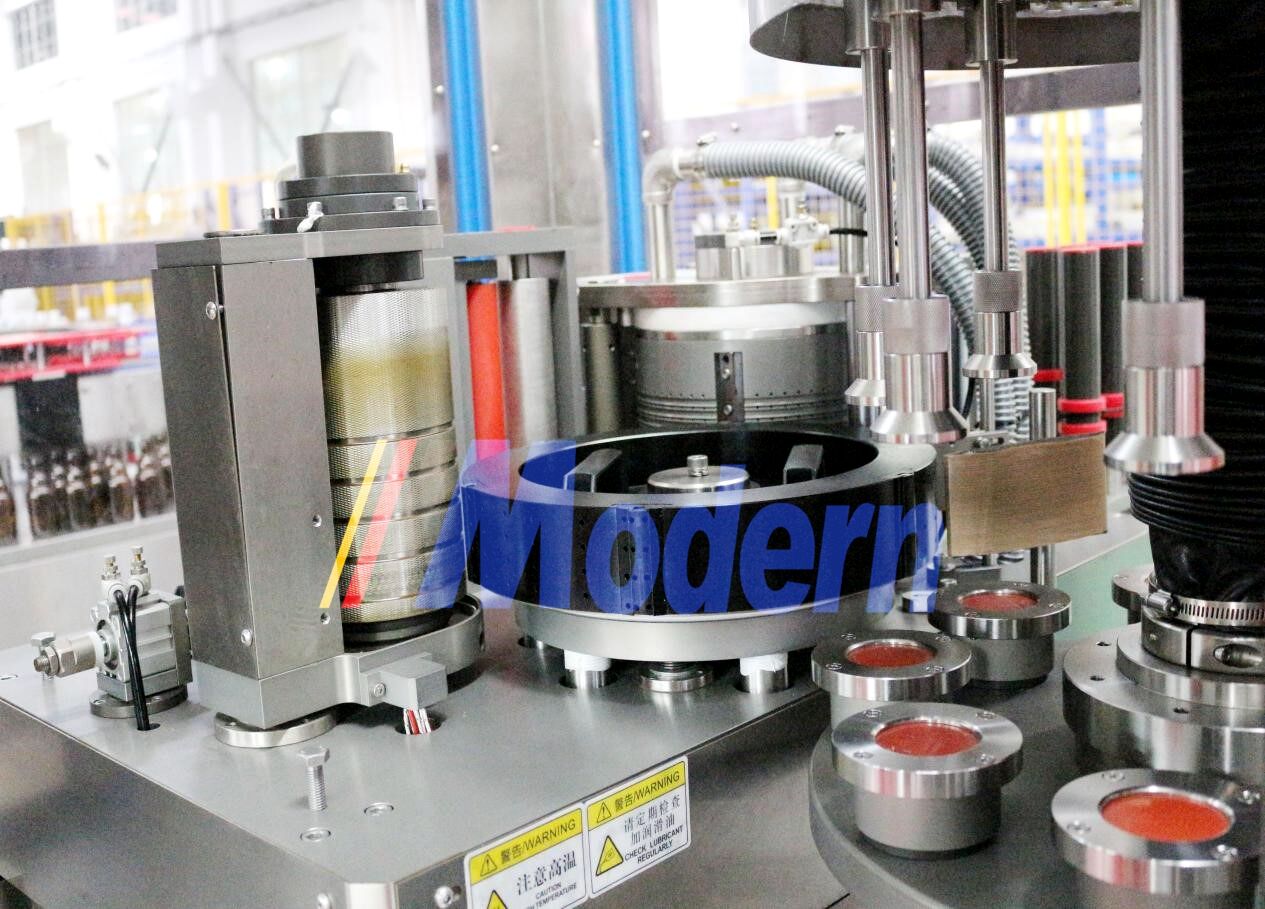

The container is picked up by the feed star wheel and conveyed to the container table. When the container is located between the container plate and the centering hood, the container starts to rotate.

The speed of the feed roller is adjusted according to the required label length to ensure constant web tension. The standard film threading device ensures the best film feeding speed. In the cutting device, the label is cut accurately, and the PLC instructions and servo motors provide the exact cut-off point.

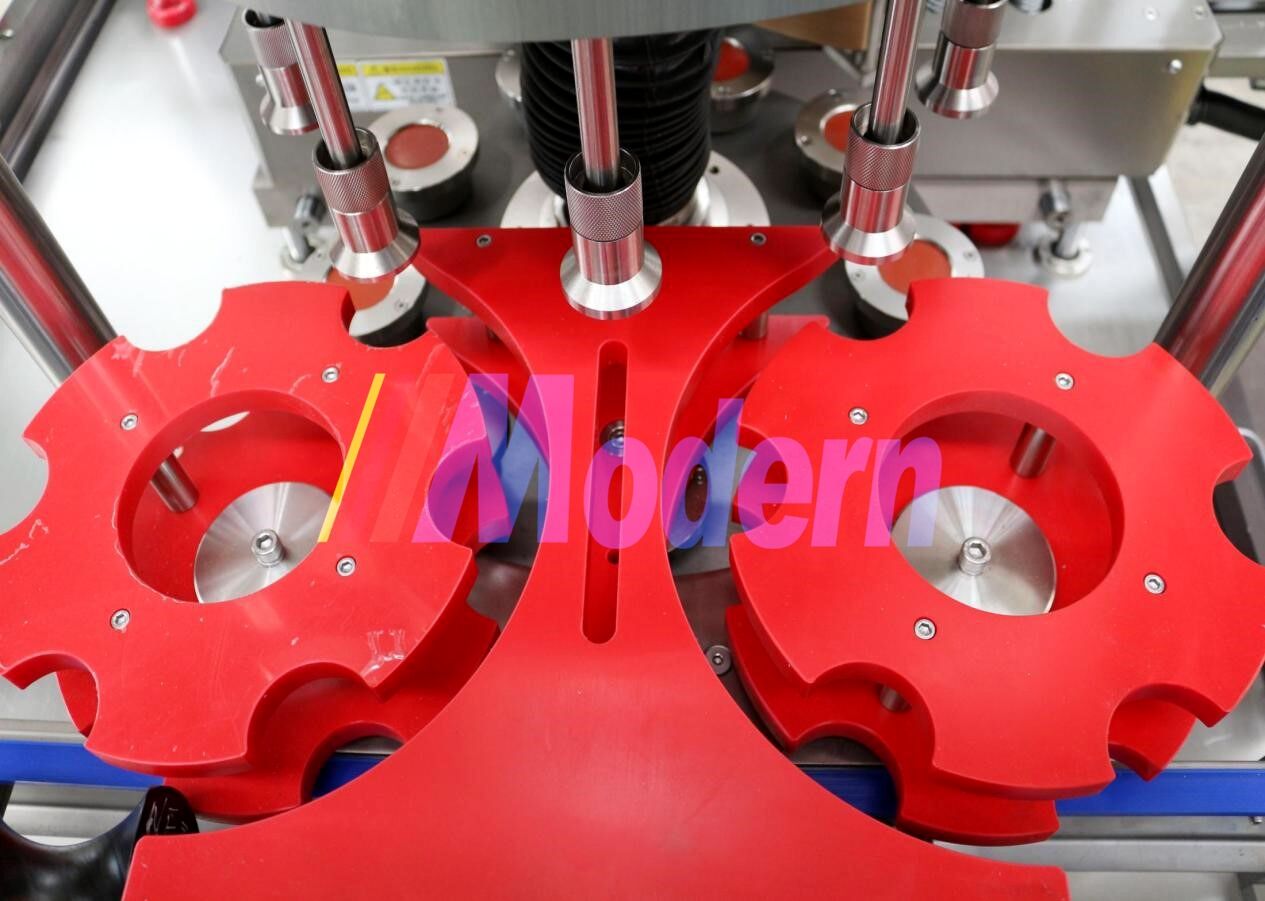

Two narrow strips of hot melt glue glue the labels together, and the heated glue rollers apply the hot melt glue to the leading and trailing edges of the label. The leading edge of the label is conveyed to the container with the glue strip. The glue strip ensures that the label is accurately positioned and firmly bonded. During the label conveying process, the container rotates and the label is tightly attached.

|

Model |

RTB-9 |

RTB-12 |

RTB-18 |

RTB-24 |

|

Label stations |

9pcs |

12pcs |

18pcs |

24pcs |

|

instillation Power |

11kw |

11.2kw |

11.5kw |

12.8kw |

|

Running power |

8kw |

8.5kw |

9kw |

9kw |

|

Capacity |

9000~12000bph |

15000~18000bph |

20000b~24000ph |

30000~36000bph |