- Overview

- Parameter

- Video

- Recommended Products

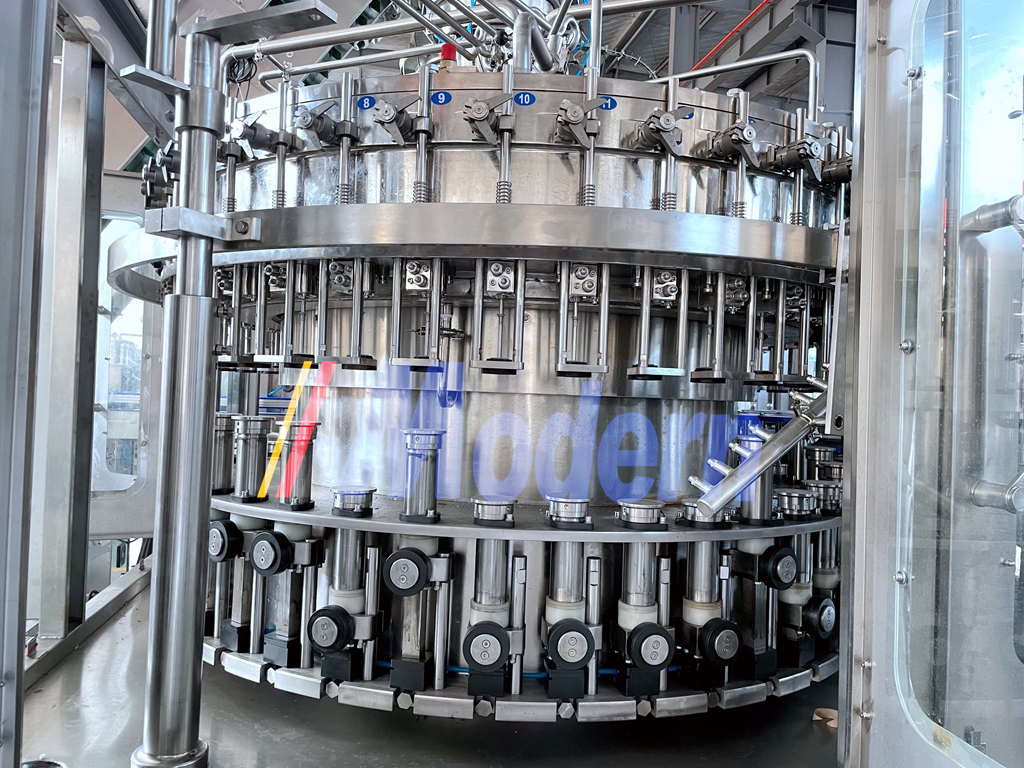

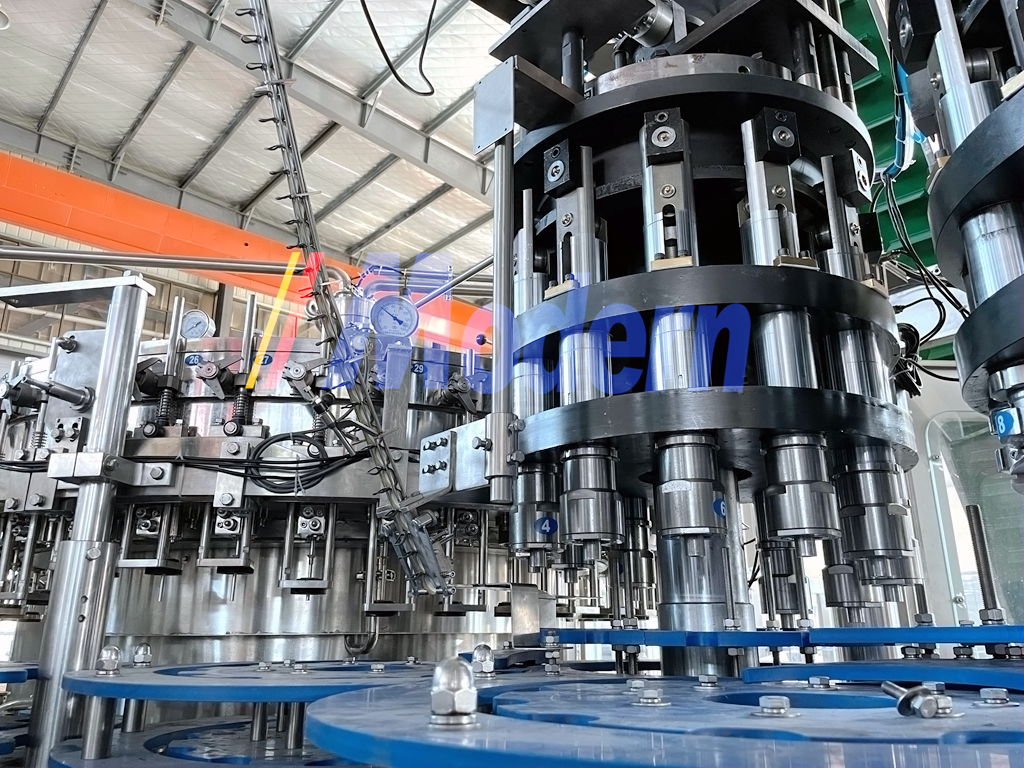

With 12 to 50 filling valves on MODERN glass bottle filling machine, soft drink manufacturers are able to handle a wide range of speeds and bottle sizes, from 150ml up to 1L. Beverage filling temperature flexibility is between 2-5°C, running at 2000-18000 bottles per hour.

The carbonated soft drink filling machine adopts advanced SIEMENS programmable controller (PLC) to control the automatic operation of the machine, cooperates with the host inverter speed adjustment, and photoelectric detection of the operation of each component, with a higher degree of automation and easy operation.

It's the perfect choice for glass bottle carbonated beverage manufacturers.

| Model | DXGF12-12-5 | DXGF18-18-6 | DXGF24-24-8 | DXGF32-32-8 | DXGF40-40-10 | DXGF50-50-12 |

| Rinsing head | 12 | 18 | 24 | 32 | 40 | 50 |

| Filling head | 12 | 18 | 24 | 32 | 40 | 50 |

| Capping head | 5 | 6 | 8 | 8 | 10 | 12 |

| Power of main motor | 1.5kw | 2.2kw | 3kw | 4kw | 7.5kw | 7.5kw |

| Total weight | 2000kg | 2500kg | 3500kg | 5000 kg | 7800kg | 9000kg |

| Capacity | 1500-2500BPH | 3000-5000BPH | 5000-7000BPH | 8000-10000 BPH | 10000-13000BPH | 13000-16000BPH |

| Bottle diameter | 50-100mm | |||||

| Bottle height | 160-320mm | |||||

| Filling method | Isobaric filling | |||||