Inconsistent Fill Levels Another common problem that some brewers can face is inconsistent fill levels. This can result in different quantities of beer in each bottle taking away from the quality and consistency of the finished product. To address this problem, the settings of the device must be verified to see if they are optimized for calibration of the fill levels. Consistent filling volumes can be maintained by regularly calibrating the apparatus, and performing quality control checks. Automatic bottle unscrambler

Another potential problem with beer bottling equipment is blockages in the bottling line. This can happen if there is debris or sediment in the beer that becomes lodged in the equipment, stopping up to flow of liquid. In order to diagnose this problem, you need to ensure that your equipment is properly cleaned and maintained in order to avoid clogs. Filters in the bottling line can also be added to prevent debris and blockage downstream. Combined half tray cardboard shrink wrap packaging machine

Instead If you can avoid them by being aware of the most common problems when using beer bottling equipment and how to solve them, then brewers is a good way that the process will flow effortlessly. It’s this maintenance, calibration, and quality control that keep the equipment operating properly and ensure that great beer is made all of the time. Here at Modern, we take pride in supplying quality beer bottling equipment to help our customers craft the ideal product time and time again.

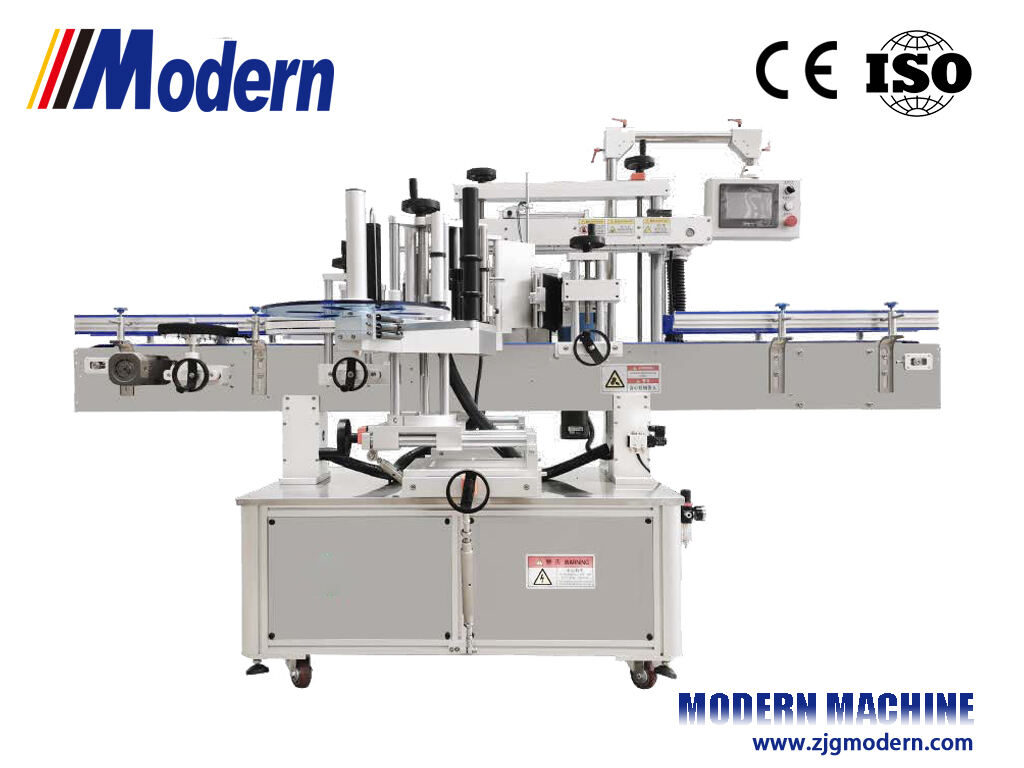

The manufacturing process of beer bottling equipment has kept pace with the changing demand for beer thanks to technological advancement. Recent developments in beer bottling machines includes automated systems. Machines like these can make the bottling process more efficient by automating it, and they minimize human error. Also, there are plenty of modern beer bottle machines that have sophisticated sensors and controls for accurate filling and capping-ensuring each bottle is filled to the correct height and sealed properly.

Another aspect of beer bottling equipment technology is that it should be eco-friendly in terms of materials and processing. More and more breweries are choosing specifically to include systems that reduce waste, and save on energy. So, for instance, some new beer bottling machines are made from recycled material or may use less water and electricity in the course of bottling. Not only are these environmentally-friendly solutions, but they cost breweries less money in the long run.

When you are looking to streamline your production process, having the best possible beer bottling machine is key. Recent beer bottle filling plant is matched with other equipment of the brewing equipments to fill your beer perfectly,which can avoid wasting resource. With high quality beer bottling equipment, you can make certain the production line is a good fit for your brewing process and that it runs smoothly and efficiently while meeting your needs.

If you are looking to make your production line more efficient with the latest beer bottling machines, a rotary filler may be necessary. These fillers are built to fill more than one bottle at a time, providing you with the ability to further speed up your bottling process. Many contemporary rotary fillers are also fitted with high-tech extras like automatic bottle height adjustment and electronic bottle control, ensuring an even fill level no longer requires manual adjustment.