When you are making juice for health reasons, choose a dark green vegetable for the base of your juice, like spinach, kale and broccoli. Today’s juice filling machines are high-speed and able to fill a large volume of bottles in very short time. Designed to withstand fast-paced production, these fillers will keep pace with this the requirements of your operation without compromising the quality of your juice filling.

Consistency is the name of the game in juice. State-of-the-art precision filling machinery guarantees each bottle is filled with the same consistent amount of juice. Such precision also has the benefit of saving you money by minimising waste and adds to the effectiveness of your production lines.

Advanced technology in today's juice filling machines may also contribute to higher productivity and long-term cost savings. From automation to intelligent sensors, these units are built with the goal of simplifying production and reducing down time. With the right technology you will get results, your juice production line runs without a problem.

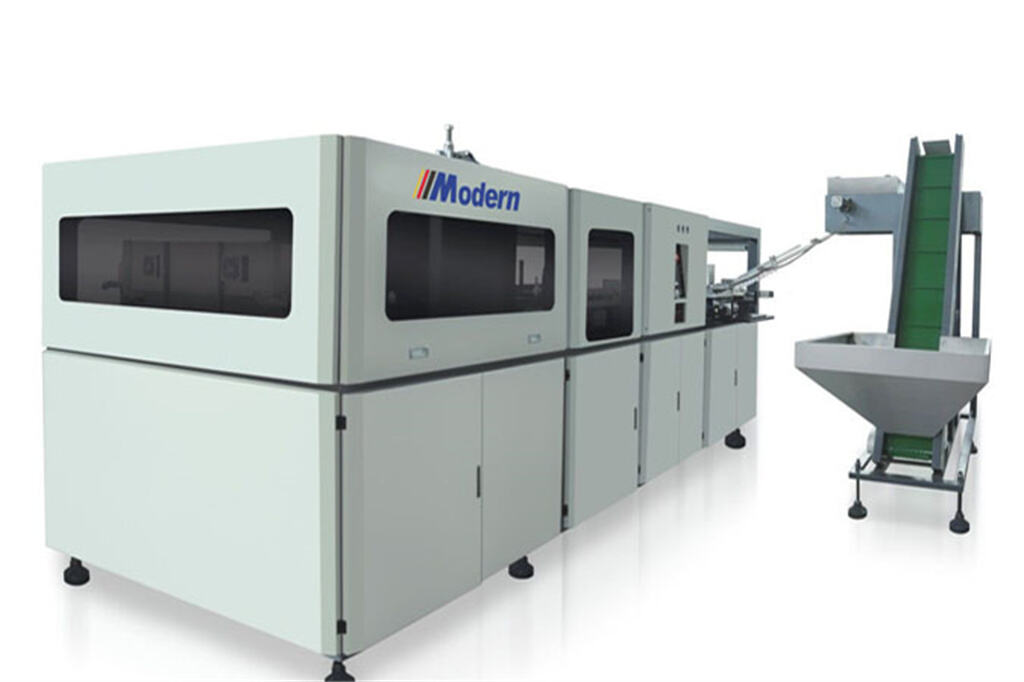

Each juice factory is different, so Modern has modular solutions for their fillers. If you need a certain size or shape of bottles, if you need some degree of automation or perfomance requirement, our experienced team will work with your from the very beginning to obtain an ideal solution for you. This kind of customization makes sure your juice production line is efficient as efficient can be.

One of the most remarkable features about Modern juice filling line machines is that they can be conveniently connected with other packaging lines. Whether you have an existing bottling line or are installing one for the first time, our equipment is designed for simple integration of your filling machine. This results in a seamless process and minimal interference with your work, and you are free to concentrate on producing smooth delicious juice.