- Overview

- Parameter

- Video

- Recommended Products

The fully automatic PET bottle blowing machine can efficiently and quickly blow bottles from 100ml to 2 liters with capacity 2000-9000 BPH. It has a complex design and well-engineered machinery to achieve a gradual and steady blowing process, uniform heating, layered preform heating system, automatic fault detection and alarm detection, can realize efficient control and stable production.

1. The man-machine interface is easy to operate. Everything is computerized, including temperature adjustment and preform distribution.

2. Preform unscrambling, loading, bottle handling and ordering are all operated by stainless steel manipulator automatically without a second contamination.

3. The circulating chilling water system can protect the bottle neck against deformation when the preform is being heated.

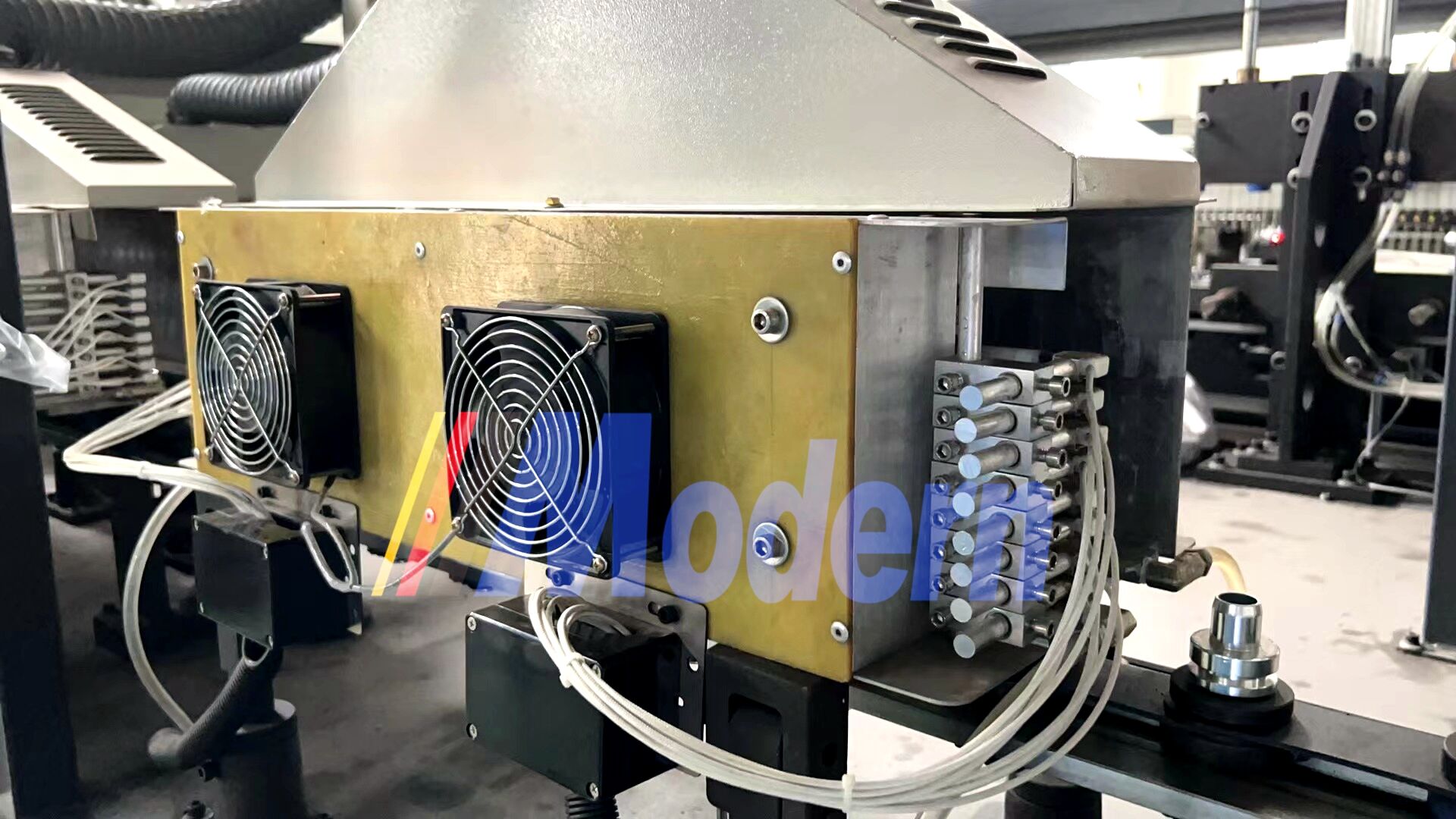

4.The homothermal heater adopts auto reflection and closed loop adjusting system which have the power supplied constantly in proportion, not affected by the fluctuation of voltage. The conveying chain is short pitched and paratactic, which helps to realize slow heating and low power consumption. As a result, the preform can be heated evenly and easy to blow.

5. The positioned installation of molds makes it possible to change molds easily within 30 minutes.

6. All the critical parts we use for the machines, such as the electrical, hydraulic and pneumatic components, servo motor, etc, are famous branded parts imported from Japan, USA and Europe,which ensures the stability and long life of our equipments.

|

Model |

Item |

CP-2000 |

CP–4000 |

CP-6000 |

C-9000 |

|

Productivity |

Depend on bottle design |

1800-2200PCS/H |

3500-4200PCS/H |

5500-6300PCS/H |

8000-9200PCS/H |

|

Product type |

Volume |

0.1-2.0L |

0.1-2.0L |

0.1-2.0L |

0.1-0.75L |

|

Body diameter |

≤100mm |

≤100mm |

≤100mm |

≤100mm |

|

|

Height |

≤310mm |

≤310mm |

≤330mm |

≤330mm |

|

|

Neck diameter |

≤38mm |

≤38mm |

≤38mm |

≤38mm |

|

|

Mold |

Cavity |

2 |

4 |

6 |

6 |

|

Mold thickness |

240mm |

240mm |

240mm |

240mm |

|

|

Mold volume |

260*240*370mm |

510*240*360mm |

640*240*360mm |

640*240*360mm |

|

|

Main machine power |

Electrical source power |

380V/220V 50/60Hz |

380V/220V 50/60Hz |

380V/220V 50/60Hz |

380V/220V 560/60Hz |

|

3Phase |

3Phase |

3Phase |

3Phase |

||

|

Rated power |

25kw |

49kw |

73kw |

97kw |

|

|

Really use power |

6.5kw |

13kw |

25kw |

32kw |

|

|

Air system |

HP air compressor |

1.6m⊃3;/min3.0MPa |

3.0m⊃3;/min3.0MPa |

6.0m⊃3;/min3.0MPa |

6.0m⊃3;/min3.0MPa |

|

LP air compressor |

1.0m⊃3;/min1.0MPa |

1.6m⊃3;/min1.0MPa |

2.0m⊃3;/min1.0MPa |

2.0m⊃3;/min1.0MPa |

|

|

Air tank |

0.6m⊃3;3.0MPa |

0.6m⊃3;3.0MPa |

1.0m⊃3;3.0MPa |

1.0m⊃3;3.0MPa |

|

|

Air dryer |

1.0m⊃3;/min3.0MPa |

2.0m⊃3;/min3.0MPa |

6.0m⊃3;/min3.0MPa |

6.0m⊃3;/min3.0MPa |

|

|

Cooling water |

Water Chiller |

3HP |

3HP |

5HP |

5HP |

|

Machine |

Size(L*W*H) |

1900*1280*1930mm |

1900*1860*1930mm |

4100*1400*1800mm |

4100*2200*1800mm |

|

Weight |

2000kg |

3600kg |

4200kg |

4800kg |

|

|

Preform unscrambler |

Size(L*W*H) |

2000*950*2480mm |

2000*950*2480mm |

2000*950*2480mm |

2000*950*2480mm |