- Overview

- Parameter

- Video

- Recommended Products

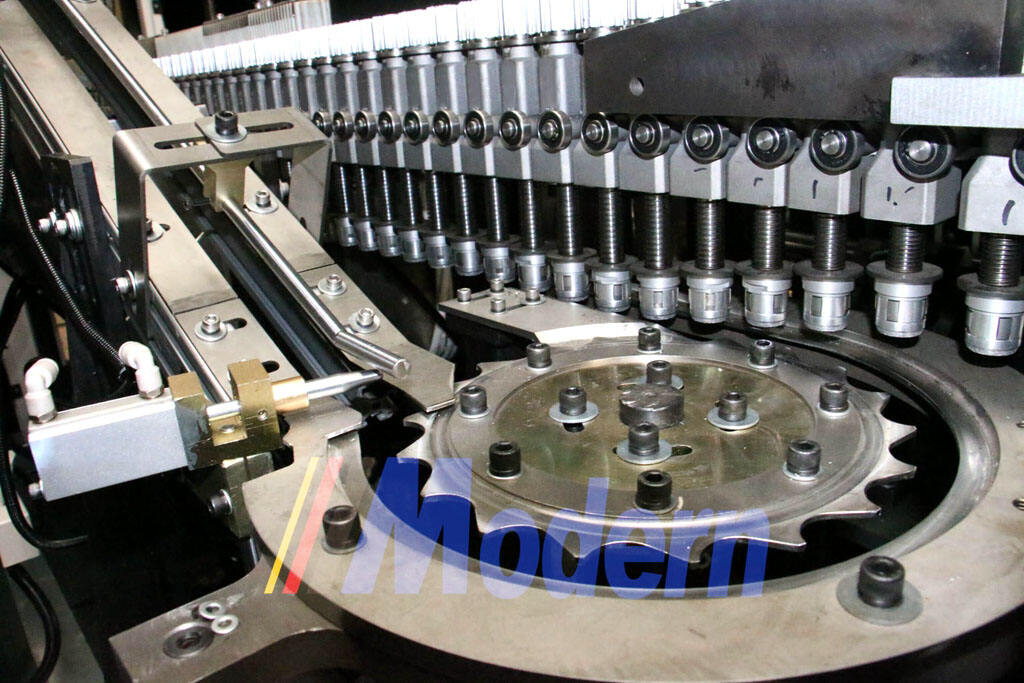

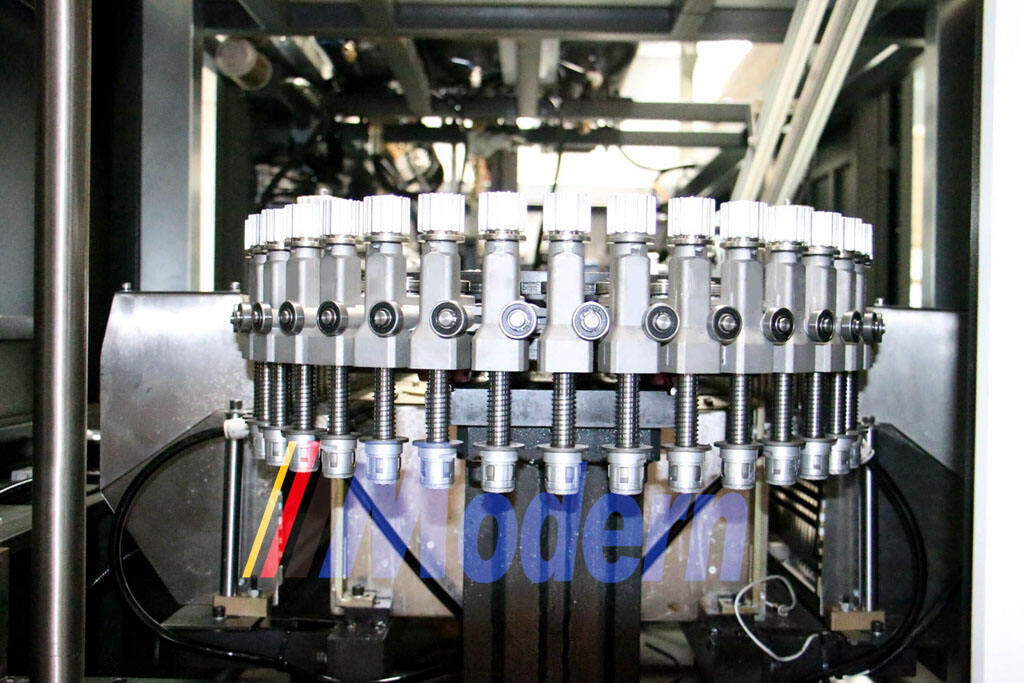

As your business grows steadily, you need a high speed blow moulding machine to match your high speed filling line. This bottle blow moulding machine is developed from the rotary bottle blowing machine. It uses full electric servo motors for driving, stretching, moulding and integrated rotary preform heating technology, which can save more than 30% power.

The continuous rotating preform feeding system is tightly combined with the machine platform, which effectively reduces the area occupied by the machine platform. The preform has no overturn and with simple structure. Continuous heating system of this high speed blow moulding machine , the heating pitch between each preform is 38 mm, which can effectively use the lamp tube heating space, highly improved the heating efficiency. Servo motor is used to ensure high-speed operation and precise positioning. This machine is suitable for drinking water, carbonated beverage, fruit juice, tea and milk product,etc in PET bottles with production capacity ranges from 6,000BPH to 20,000BPH based on 500ml water bottle.

|

Model No. |

K4 |

K6 |

K8 |

K10 |

|

Production Capacity(BPH) |

6000-8000 |

9000-12000 |

10000-15000 |

16000-20000 |

|

Container volume(L) |

0.3-1.5 |

0.3-1.5 |

0.3-0.6 |

0.3-0.6 |

|

Bottle height(mm) |

120-330 |

120-330 |

120-330 |

120-230 |

|

Bottle diameter(mm) |

45-105 |

45-105 |

45-105 |

45-65 |

|

Preform length(mm) |

50-130 |

50-130 |

50-130 |

50-130 |

|

Host dimensions(m) |

4.5*1.5*2.67 |

5.4*1.6*2.67 |

6.9*1.6*2.67 |

7.2*1.6*2.67 |

|

Bottle unscrambler dimensions(m) |

2*2*2.5 |

2*2*2.5 |

2*2*2.5 |

2*2*2.5 |

|

High pressure air pressure(Mpa) |

4 |

4 |

4 |

4 |

|

Voltage(V) |

380 |

380 |

380 |

380 |

|

Installation power(kw) |

60 |

95 |

127 |

159 |

|

Actual power(%) |

30-60 |

30-60 |

30-60 |

30-60 |

|

Mold cooling(HP) |

5 |

10 |

12 |

12 |

|

Applicable material |

PET |

PET |

PET |

PET |

|

Weight(T) |

4 |

6 |

6.5 |

7 |