- Overview

- Parameter

- Recommended Products

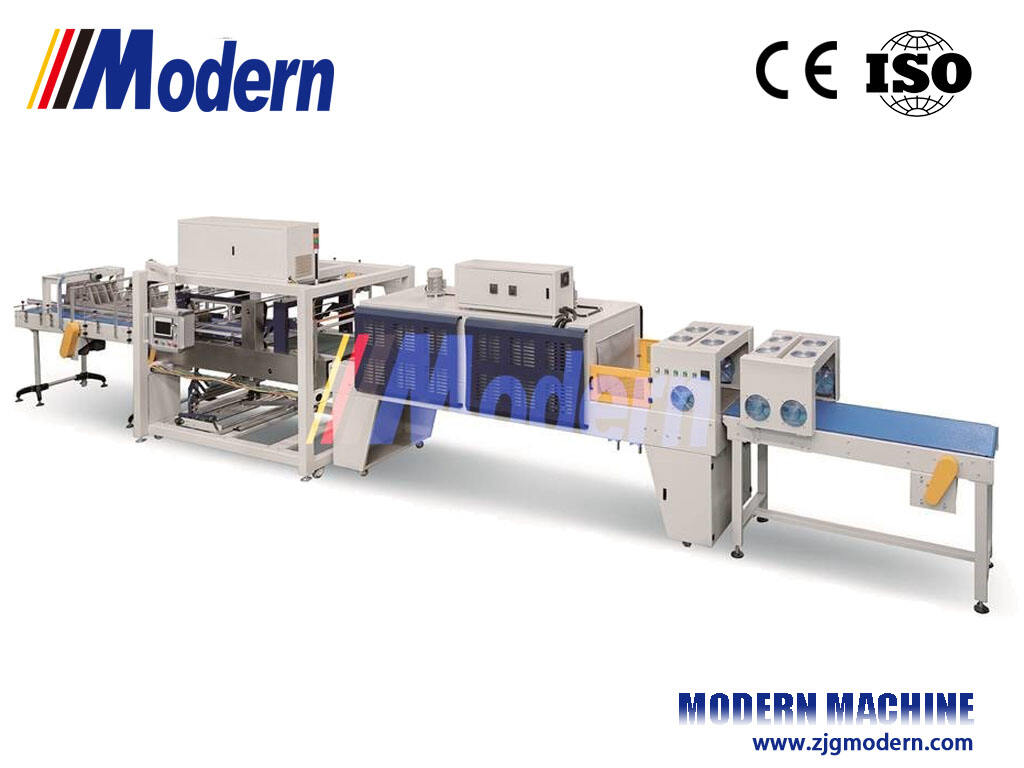

This linear shrink wrap machine has higher capacity (20-30 packages per minute) than normal “L” type machine. It’s used for wrapping on the outside of the product or package by shrink film. After heating, the film shrink machine shrinks the product or the package tightly. Fully display the appearance of the item.

The linear shrink wrap machine can be used alone or in conjunction with other equipment to form a filling or packaging line. The machine automatically arranges, gathers, and aligns PET beverage bottles or other similar items, then wraps them with shrink film. After heating, cooling, shaping, and shrinking, the finished product is finally obtained. The packaged products are firmly tied, beautiful in appearance, and easy to open. They are widely used in food, medicine, chemical and other light industrial products industries.

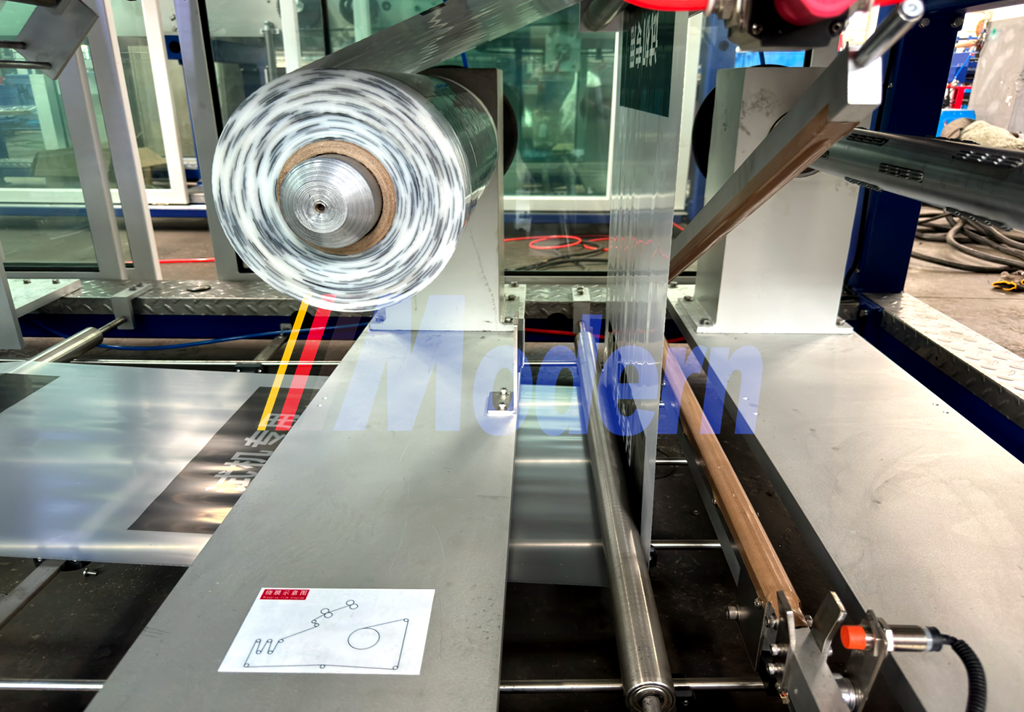

1) The temperature can be controlled automatically and changed as required.

2) Isothermal sealing cutter

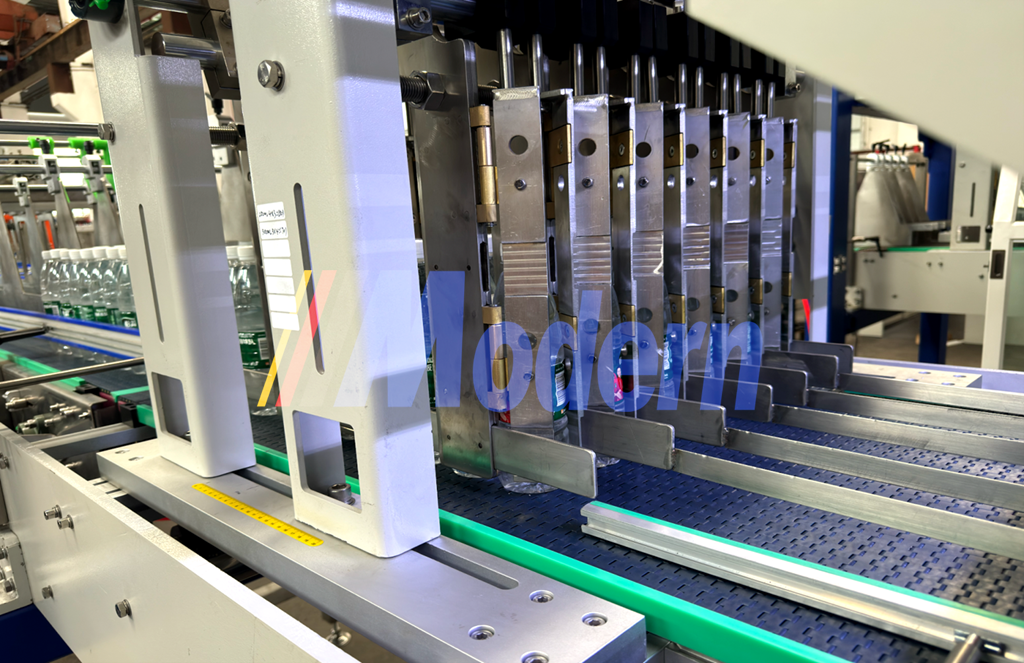

3) Original guide bar cylinder with steady operation

4) Programmable logic controller (PLC) control

5) Non bottom support packaging, suitable for package with different bottle diameters and different combinations

6) Simple operation and easy repair.

|

Model |

MB-35 |

|

Facility overall size |

L14000×W1200×H2100mm |

|

Main equipment |

3400×1250×2350mm |

|

Shrinkage machine |

4200×1200×1700mm |

|

Conveyor |

5200×1300×950mm |

|

Wrappage max size |

L2400×W650×H450mm |

|

shrinkage film material |

PE |

|

shrinkage film thickenss |

0.08mm |

|

thermo shrinkage tunnel max temperature |

160 - 260° adjust at will |

|

max output per minute |

30-40 bag |

|

facility power |

35Kw |

|

actual power |

30Kw/h |

|

pressure requirement |

380V/50-60HZ |

|

facility weight |

2800 |

|

air pressure |

0.6-0.8mpa |

|

working noise |

≤65db |

|

import bottle convey belt width |

541mm |

|

fan |

1.1Kw 3set 380V, 60W 6set 380V |